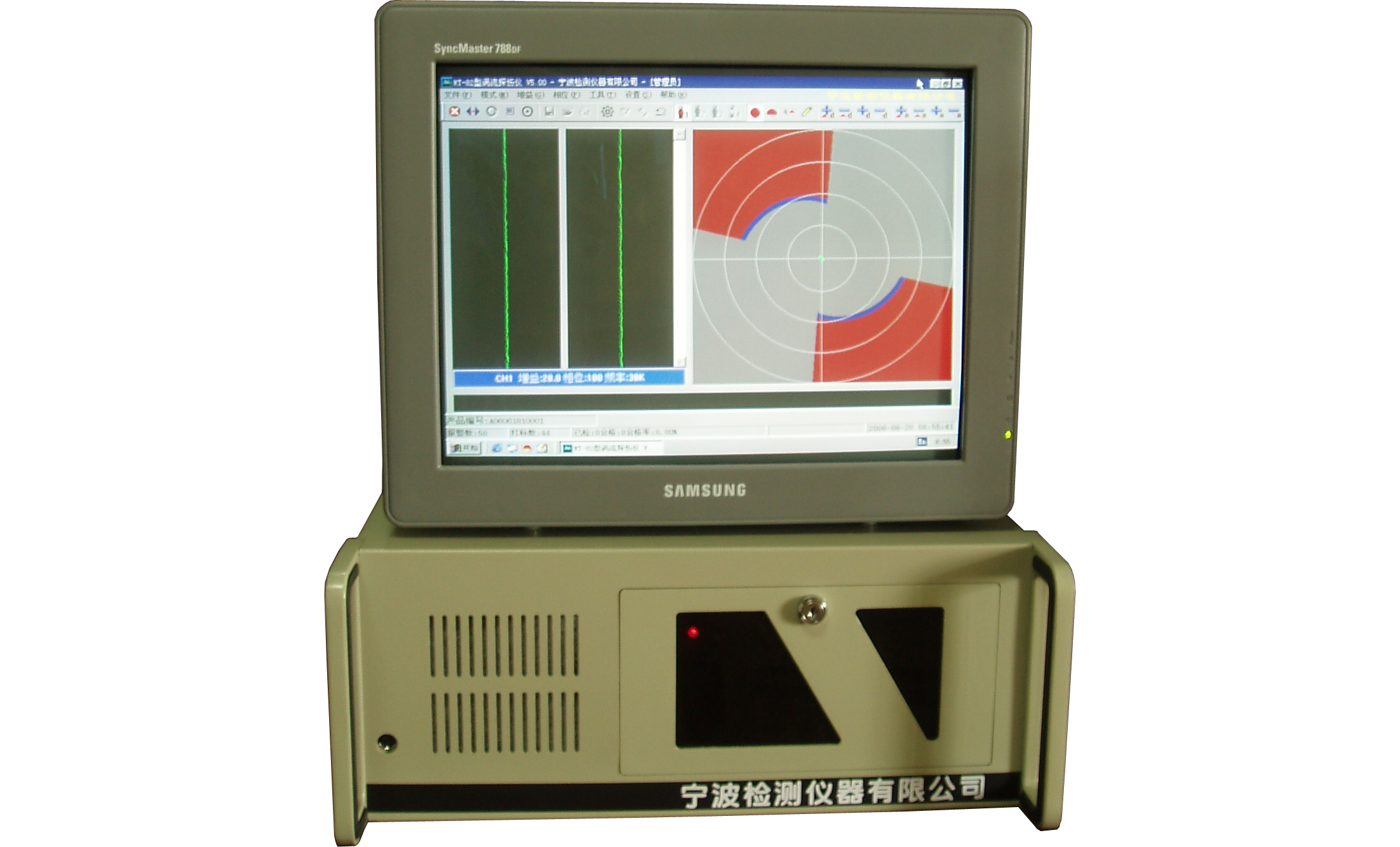

Main Technical Parameters

- Frequency range: 100Hz-2MHz set as need, suitable for any metallic material.

- Magnification: 0-70db, step for 0.1db.

- Phase: 0°- 360°, step for 1°

- Two independent optional frequency.

- Automatic phase, amplitude analysis.

- Automatic zero system: Zero intervals can be set.

- Three different style of alarm area, and can be applied to any modes.

- Cut start and end signal function.

- Auto-screen/tracking impedance showed, and can be set interval or cancel.

- Automatic delay alarm system, and delay time can be set.

- Automatic delay marking system, and delay time can be set.

- Replay testing signal and two-way access, can automatic save this in hard disk, and you can burn a disc for permanent preservation.

- Perfect documents process function, and customized production of standard parameters.

- Automatic high-speed analog/digital electronic equilibrium.

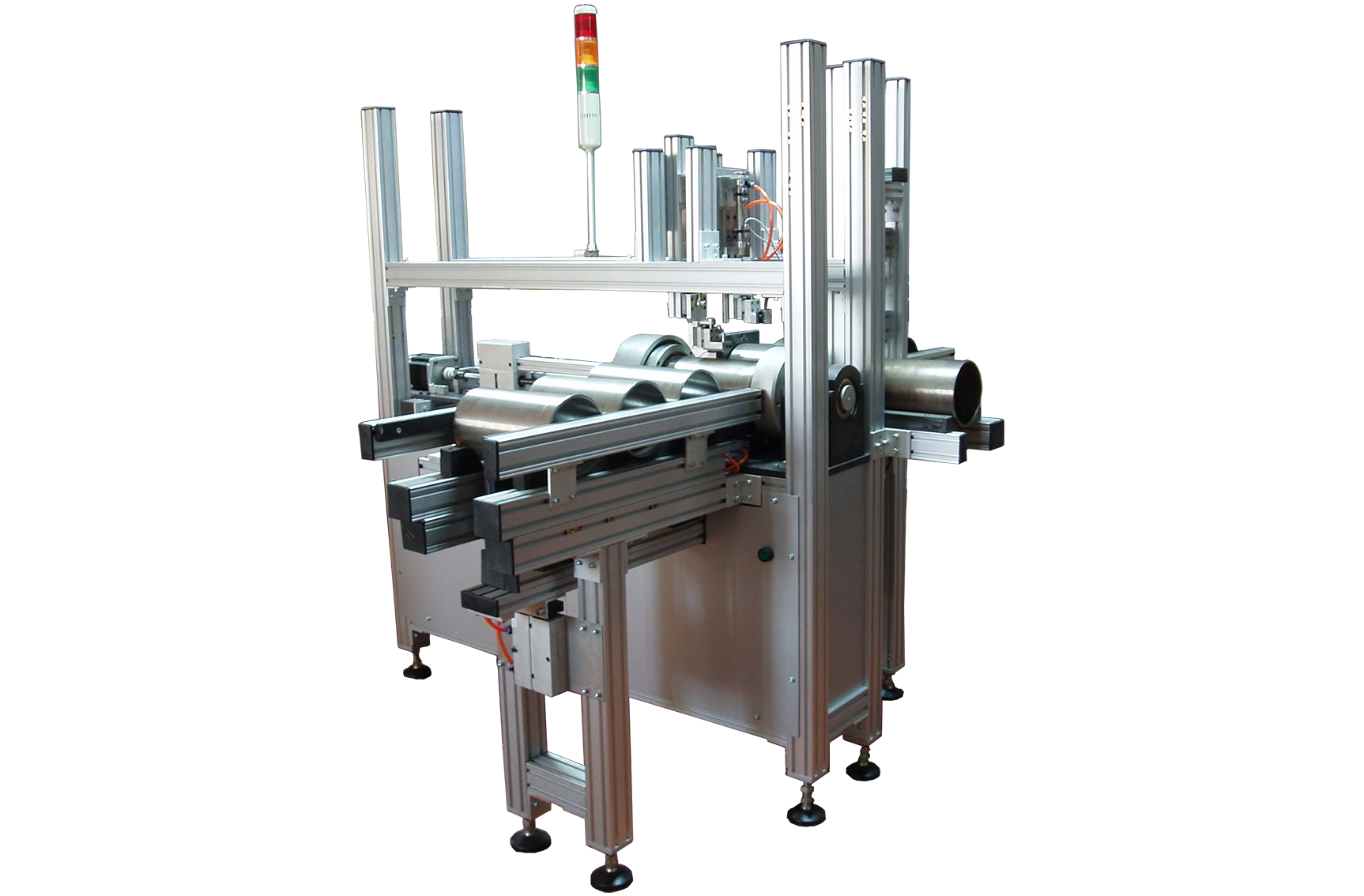

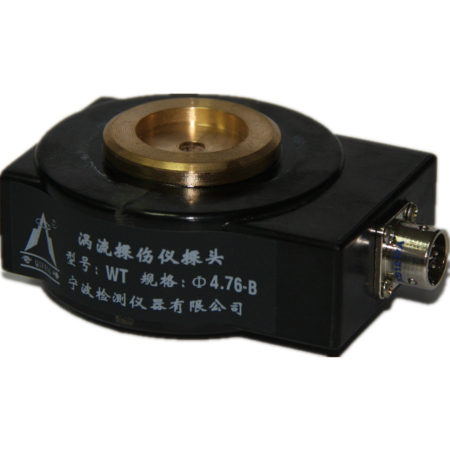

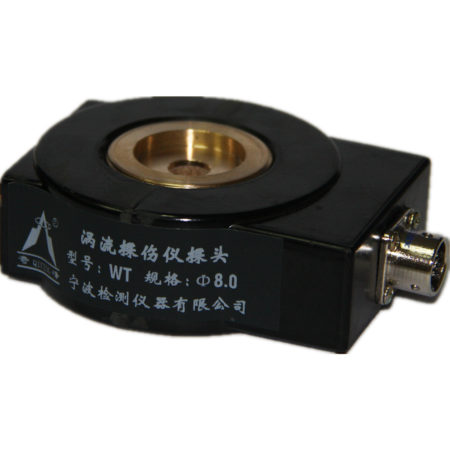

- Allocate every probe: Out-through probe, rotational-scan probe, etc.

- Suitable for online quality testing of metal pipe and bar manufacturers.

System applicable standards:

- China: GB/T 14480–93, GB/T 7735—98

GB/T 5248–98, GB/T 5126—2001

GB/T 12969.2, GB/T 11260–96

- Japan: JISH 0502

- S.A: ASTM-E 243–97

- Germany: DIN 54141

Applications

- Online nondestructive testing on copper tube, steel pipe, stainless steel pipe, welded pipe, aluminum-plastic pipe, steel wire, bimetallic tube, optical cable, alclad steel wire, aluminum wire and metal bar production-line

- Nondestructive testing on oil casing, sucker rod, hollow shaft, etc.

- Nondestructive testing on condenser tube, air conditioner pipe, automobile oil pipe, etc.

- Nondestructive testing on various kinds of metal pipe, bar, wire, etc.